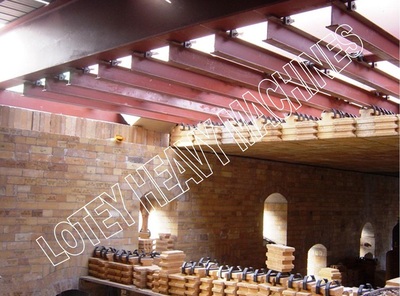

REHEATING FURNACE

Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperature. The charge could be in the form of billets, blooms, slabs or ingots.The type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom fired.The fuel used could be either oil or gas. The burners are located in a manner so as to achieve uniform heat distribution. The radiation heat energy is efficiently transferred through the useful heat transfer area created by the charge bed.The furnace is basically divided into three zones namely preheating, heating and soaking zones. The actual heating takes place in the heating zone. The temperature uniformity up to desired limits between the core and the surface is achieved in the soaking zone. The flue gases move in a direction opposite to that of the charge thereby ensuring considerable amount of waste heat recovery by convection in the preheating zone, which is also termed as the recuperative zone.

Our furnaces are highly fuel efficient due to proper roof profile / zonal distribution, optimum preheating / recuperative zone lengths, proper burner / flue port locations and good instrumentation including furnace chamber pressure control eliminating atmosphere air ingress, which also reduces the scale loss and decarb of the charge.

Our furnaces are highly fuel efficient due to proper roof profile / zonal distribution, optimum preheating / recuperative zone lengths, proper burner / flue port locations and good instrumentation including furnace chamber pressure control eliminating atmosphere air ingress, which also reduces the scale loss and decarb of the charge.

|

BILLET / BLOOM REHEATING FURNACE (Entire Range)

|

OTHER FURNACE COMPONENTS & MACHINES WE MANUFACTURE :

|